Equip Your machine

With Open source CMMS software

Offer your customers immediate value. Embed our open source CMMS & OEE platform to deliver performance insights, predictive alerts, and downtime reduction

For Machine Builders

The Software kit covers all industry standards, with the Historian App, OEE, open source CMMS, and downtime tracking ,you can make sure your machine is running seamlessly

OEM Benefits

Essential tools for your success.

Built-in Differentiation

Stand out from competitors by shipping machines with built-in deep analytics — effortlessly.

Customer Stickiness

your clients can track performance and maintenance on their own. When they rely on your software, they stay loyal to your brand.

Minimal Integration Effort

Open-source and flexible embed the CMMS with your own UI or use ours. Integration is lightweight, fast, and no overhead.

Lower TCO for End Users

Our open-source platform can be used freely and customized as needed, helping end users save on software licenses.

Features

Industry 4.0 in one step

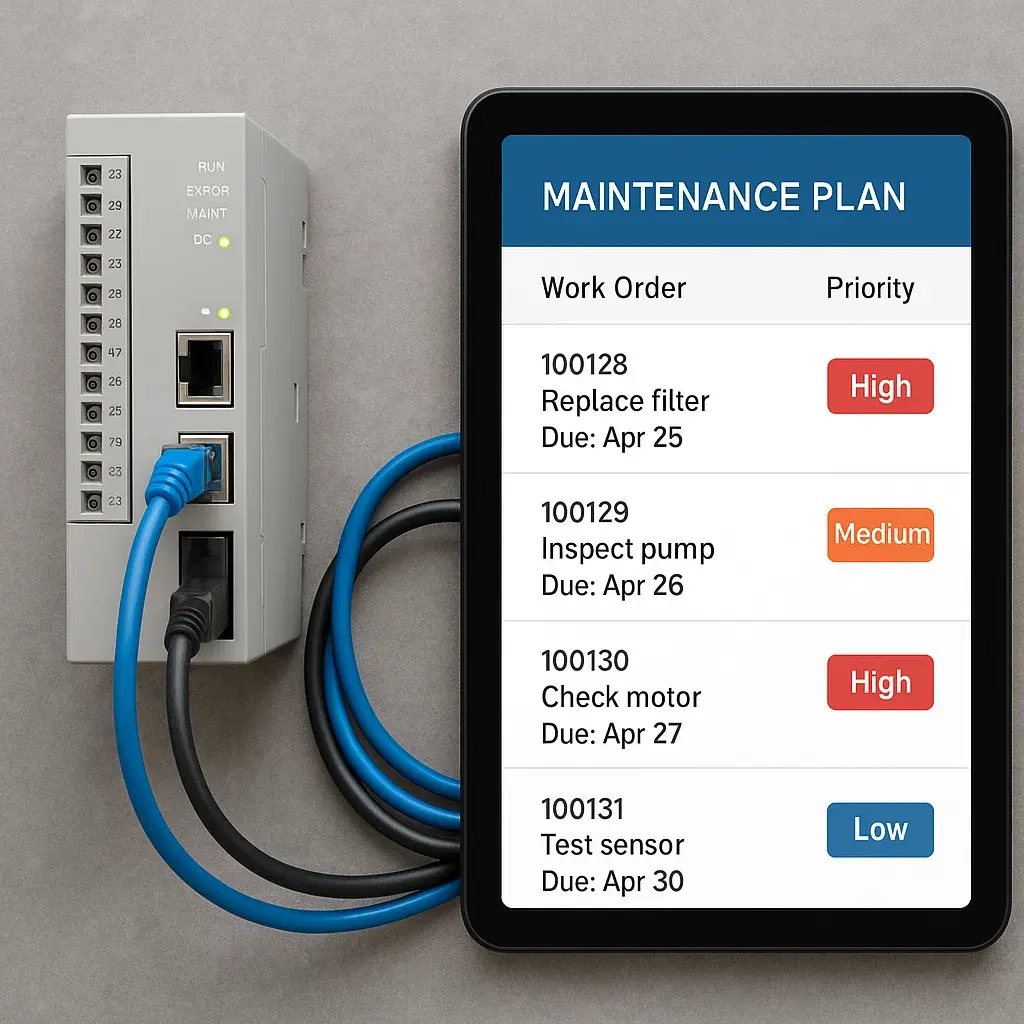

Preventive maintenance

Save time and centralize all maintenance activities in one place. Schedule tasks, track service history, and prevent unexpected breakdowns.

Asset Management

Extend machine life by keeping assets organized, monitored, and under control.

Machine metrics

Boost efficiency by tracking and analyzing the performance of all your machines.

Dashboards

Make smarter decisions with real-time data. Visualize your production data in real-time and on the go.

New Revenue Streams for OEMs

Offer CMMS as a value-added service. Provide your customers with subscription-ready maintenance features and generate recurring revenue while improving machine up-time.

Fast OEM Integration

One For All

Our platform connects to standard PLC protocols and historian systems, letting you embed CMMS into your machines without heavy development. Reduce integration time and accelerate go-to-market.

How it works

Requirements & Discovery

We start by gathering your needs: machine type, customer use cases, required integrations (PLC, sensors, ERP), and long-term goals.

Design & Customization

We adapt the open-source CMMS to your brand and your machine. We configure modules, dashboards, and workflows so they align with your requirements.

Integration & Testing

We connect the software to your machines via IoT gateways, simulate real production scenarios, and validate maintenance workflows to ensure reliability.

Deployment & Training

The solution is rolled out to your machines. We provide documentation, train your staff, and make sure your customers can use it with minimal friction.

Support & Scaling

We stay available for updates, remote monitoring, and scaling the same solution across multiple machine models.

Our Partners trust us to provide top-notch software solutions

Schedule a personalized demo with us